HRC2 Anti Arc Flame Retardant Clothing

HRC2 flame retardant clothing is a personal protective equipment designed for moderate arc flash risk (ATPV ≥ 8 cal/cm ²), widely used in industries such as power operation and maintenance, petrochemicals, and metal processing. The following provides a detailed analysis from the aspects of technical standards, material processes, applicable scenarios, cleaning and maintenance, and key points for selection:

1、HRC2 Flame Retardant Clothing Core Technical Standards and Certification

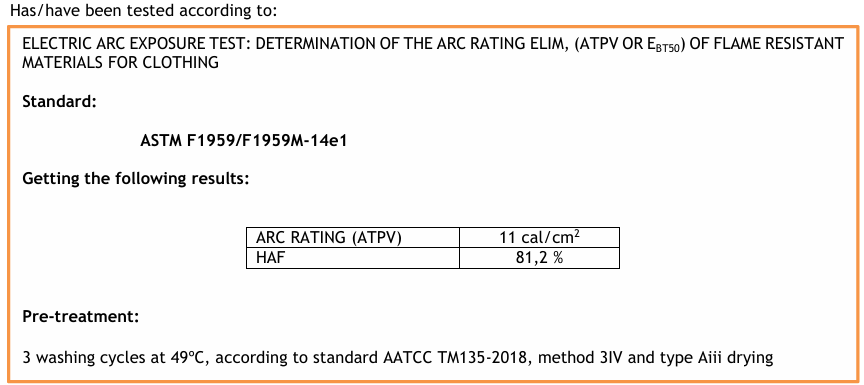

According to the NFPA 70E standard, the arc protection level (HRC) of HRC2 requires materials to have an arc thermal protection value (ATPV) of at least 8 cal/cm ². At the same time, the product needs to be certified by NFPA 2112 (flash fire protection) and ASTM F1506 (flame retardant performance), and some products also comply with EN 11612 (European flame retardant standard) and UL certification.

Material performance requirements

Permanent flame retardant fabric: made of aramid blend, it has flame retardant, anti-static and wear-resistant properties, suitable for high temperature environments.

Flame retardant treatment of pure cotton or cotton brocade: using pure cotton or cotton brocade blended fabric, treated with Proban ® Or Pyrovitex ® Process treatment can withstand 100 washes while maintaining flame retardancy.

Special blending technology: combining pre oxidized fibers (OPF), aramid, and viscose fibers, while providing anti welding splash protection.

2、HRC2 Flame Retardant Clothing Typical application scenarios

Electricity and Energy Industry

Medium risk operations such as substation maintenance and maintenance of low-voltage distribution cabinets. For example, technicians need to wear HRC2 flame retardant jackets or jumpsuits when debugging electrical equipment to prevent second degree burns caused by arc flash.

Petrochemical industry

The hot work scenarios in refineries and chemical plants must meet both flame retardant and anti-static requirements (EN 1149), and can withstand the risk of sparks in oil and gas environments through dual certification.

Manufacturing and Welding Scenarios

HRC2 protective clothing can protect against molten metal splashes and local flash fires during welding and cutting operations in the machining workshop. Some products adopt tear resistant mesh design to enhance durability.

3、HRC2 Flame Retardant Clothing Structural design and functional details

Enhanced protective performance

Multi layer protective structure: By stacking double-layer fabrics, additional protection is provided in critical areas such as the chest.

Anti static treatment: Some products are added with conductive fibers, which meet the EN 1149-5 standard and are suitable for flammable and explosive environments (such as oil and gas storage tank areas).

Comfort design

Breathable heat dissipation: Using mesh lining or underarm ventilation holes, it can keep you dry even after long-term wear.

Ergonomic cutting: The three-dimensional cutting and elastic waistband design ensure smooth movement during work and avoid a sense of restraint.

4、HRC2 Flame Retardant Clothing Cleaning, maintenance, and service life

Cleaning standards

Machine washing requirements: Use neutral detergent and avoid chlorine bleach or softener (which may increase the loss rate of flame retardants by 40%). It is recommended to change new clothes every 100 washes to ensure safety performance.

Drying method: Natural air drying or low-temperature drying (≤ 60 ℃), avoid direct sunlight or high-temperature baking.

Scrap standard

When the damaged area is greater than 5cm ², the seam is open or the flame retardant performance test is not qualified, it needs to be replaced forcibly.

5、 Key points for selection and cost reference

Certification compliance

Priority should be given to products certified by NFPA 2112, ASTM F1506, and UL,

Special industries require additional attention to anti-static (EN 1149) or anti chemical splash (EN 13034) certification.

price range

customized requirements

Customization can be made based on the company logo, size (such as European/American), and special features (such as UV protection), supporting reflective strips or pocket designs.

6、 Risk scenario comparison and protection upgrade

Risk level ATPV value (cal/cm ²) Recommended protective equipment for typical scenarios

HRC1 ≥ 4 Low voltage equipment maintenance lightweight flame retardant shirt

.png)

HRC2 ≥ 8 substation maintenance and welding operations flame retardant jacket/jumpsuit

HRC3 ≥ 25 High voltage switch operation multi-layer aramid protective suit

HRC4 ≥ 40 arc welding, aluminum plated fire resistant clothing for ultra-high voltage environments