NFPA2112 Certified FR Cotton Flame Retardant Fabric

NFPA2112 certified FR cotton fabric is a specialized material designed to protect industrial workers from flash fires and thermal hazards. Here’s a comprehensive overview based on the latest standards and industry practices:

1. NFPA 2112 Standard Requirements

NFPA 2112 (2023 edition) mandates rigorous testing for flame-resistant garments, including:

ASTM F1930 Manikin Test: Simulates a 3-second flash fire exposure at 2 cal/cm², allowing ≤50% predicted body burn (2nd/3rd degree) .

ASTM D6413 Vertical Flame Test: Requires after-flame time ≤2 seconds, char length ≤4 inches, and no melting/dripping .

Thermal Stability Test: Fabric must withstand 260°C (500°F) for 5 minutes without shrinkage >10% or structural failure .

Component Testing: Zippers, threads, and closures must also pass high-temperature and flame resistance tests .

The 2023 update emphasizes annual recertification of samples and expanded testing for barrier face coverings .

2. FR Cotton Fabric Composition

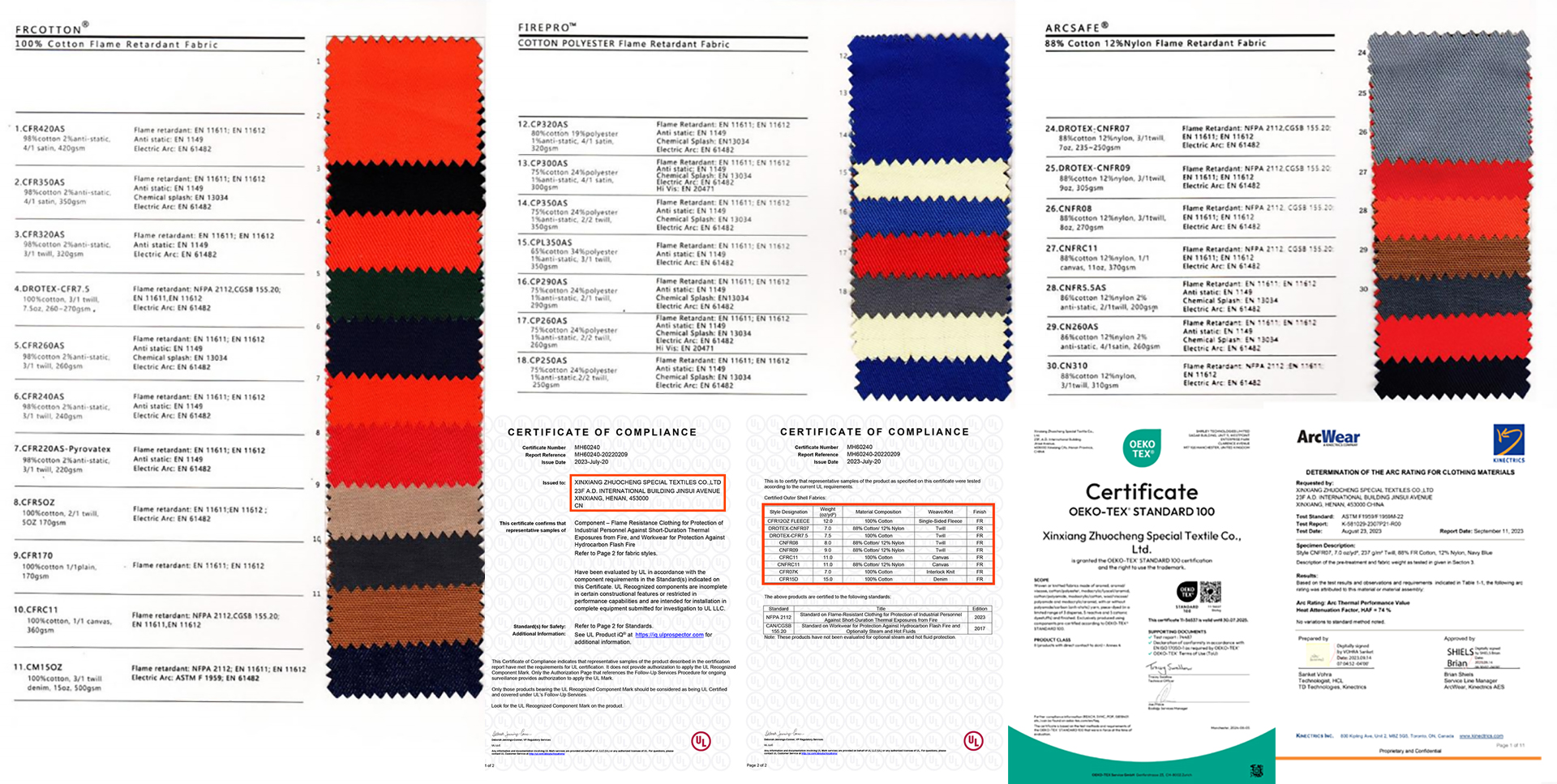

100% Cotton: Treated with durable flame retardant finishes (e.g., Proban®) to achieve FR properties. Examples include DROTEX’s CFR-265 (265 GSM twill) for welding and oil/gas sectors .

Blends:

98% Cotton + 2% Antistatic Fibers: Common in high-visibility garments (e.g., fluorescent yellow fabrics) to prevent static buildup in explosive environments .

88% Cotton + 12% Nylon: Used in knitted terry fabrics for enhanced abrasion resistance .

Key Features: Breathability, durability, and low formaldehyde content (e.g., <75 ppm in some certified products) .

3.Certification and Compliance

- Third-Party Certification: UL certification is common, though other accredited bodies (e.g., CSA) are acceptable. Garments must bear the certification mark on labels .

- OEKO-TEX® Standard 100: Some suppliers (e.g., Xinxiang DROTEX) offer FR cotton fabrics with this eco-certification, ensuring low chemical toxicity .

- OSHA Compliance: NFPA 2112 is recognized by OSHA as a benchmark for flash fire protection under 1910.132 .

4. Applications

High-Risk Industries: Oil/gas, petrochemical, welding, mining, and utilities.

Garment Types: Coveralls, shirts, pants, and gloves. For example, 350 GSM FR cotton with antistatic properties is used in safety wear requiring both flame resistance and visibility .

5. Maintenance and Care

Laundering: Use non-bleach detergents and avoid chlorine bleach, as it degrades FR finishes. Professional industrial laundering is recommended to maintain performance through ≥50 washes .

Storage: Store in cool, dry conditions to prevent mildew or chemical contamination.

6. Cost Considerations

Price Range: FR cotton fabrics typically cost $2–$4 per meterfor standard weights (220–350 GSM), with blends or certifications (e.g., OEKO-TEX) adding 10–20% to costs .

Factors Influencing Cost: Fabric weight, antistatic/hi-vis treatments, and third-party certifications (e.g., UL, OEKO-TEX) .

7. Environmental Impact

While FR cotton uses chemical finishes, suppliers like drotex ensure treatments meet EU REACH standards. For eco-conscious buyers, OEKO-TEX-certified options minimize harmful residues .

By adhering to these guidelines, industries can select NFPA 2112-certified cotton FR fabrics that prioritize safety, durability, and compliance. Always verify certifications with suppliers and follow maintenance protocols to ensure optimal performance.