How to choose a flame-retardant fabric supplier?

October 12, 2021

In recent years, with the growth of people’s safety awareness, people’s requirements for protective products have become higher and higher, and flame-retardant fabrics have gradually become a hot topic of concern. An excellent supplier of flame-retardant fabrics should meet several basic requirements. Require.

1. Quality is the first indicator for evaluating suppliers of flame-retardant fabrics. Only suppliers with a complete quality control system can continue to supply flame-retardant fabrics with stable quality.

2. Reasonable price, sufficient production capacity, able to ship on time.

3. High-quality service, timely communication to solve the problems in each link.

For more than 20 years, Zhuocheng Textile has focused on the research and development and production of special protective fabrics, and has accumulated rich experience and resources in the field of special protective. Life is priceless, quality is the foundation, and a strict quality control system is implemented.

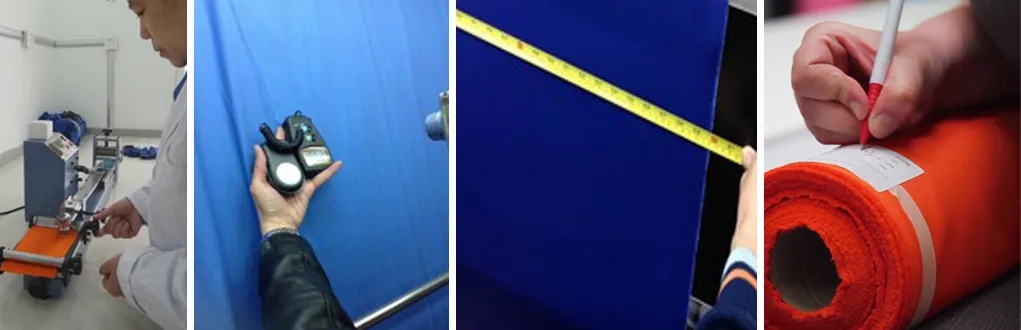

1. Control the quality from the source, select or custom-weave grey fabrics according to the contract requirements. For custom-weave grey fabrics, our company will conduct a comprehensive test on the grey fabrics after they are off the machine in the textile factory, and then weave them in batches after reaching the contract requirements. After the grey fabric enters the factory, the physical index of the grey fabric will be checked again, and the grey fabric will be randomly inspected for more than 30%, and then put into production after confirming that the quality is the same.

2. After dyeing, test the various indicators of the colored fabric (strength, color fastness, shrinkage, weight, width), and conduct a comprehensive inspection of the appearance of the fabric. The QC will write the various indicators of the colored fabric in written form. The appearance quality evaluation results are reported to the production department.

3. Sampling test (more than 30%) before putting into production and finishing, and then entering the finishing process. During the finishing process, our company will carry out upper, middle and lower sampling tests on each box (about 1000 meters) of fabric to ensure the function of the fabric Unanimous. Test the shrinkage rate of about 1500 meters of fabric to ensure that the shrinkage rate is consistent. After the bulk cargo is finished, take samples and test again before the finished products are finished. The inspection, coiling and packaging of the finished products can be started only if the indicators meet the contract requirements. Finished product inspection is carried out according to the American standard four-point system, which guarantees a 99% first-class rate of finished products.