Flame Resistant Knit Fabric & Inherent Fabric to Make FR Coverell

FR Knit Fabric vs. Inherent Fabric: Choosing the Right Material for FR Coveralls

When it comes to workplace safety in high-risk industries—think oil & gas, electrical work, or firefighting—FR Flame Resistant coveralls are more than just clothing: they’re lifelines. But not all FR coveralls are created equal, and the fabric they’re made from can mean the difference between protection that holds up and failure when it matters most.

Two key players in the FR fabric world are FR knit fabric and inherent flame retardant fabric. Let’s break down what makes each unique, how they perform in real-world scenarios, and which one might be right for your FR coverall needs.

What Are FR Coveralls, and Why Does Fabric Matter?

FR coveralls are full-body protective garments designed to resist ignition, slow burn spread, and self-extinguish when exposed to flames or high heat. They’re critical for workers facing flash fires, electric arcs, or molten metal splatters.

The fabric is the heart of their performance. It determines:

How well they block heat and flames

Comfort (breathability, stretch, weight) during long shifts

Durability (how they hold up to washes, abrasion, and repeated use)

Cost and maintenance needs

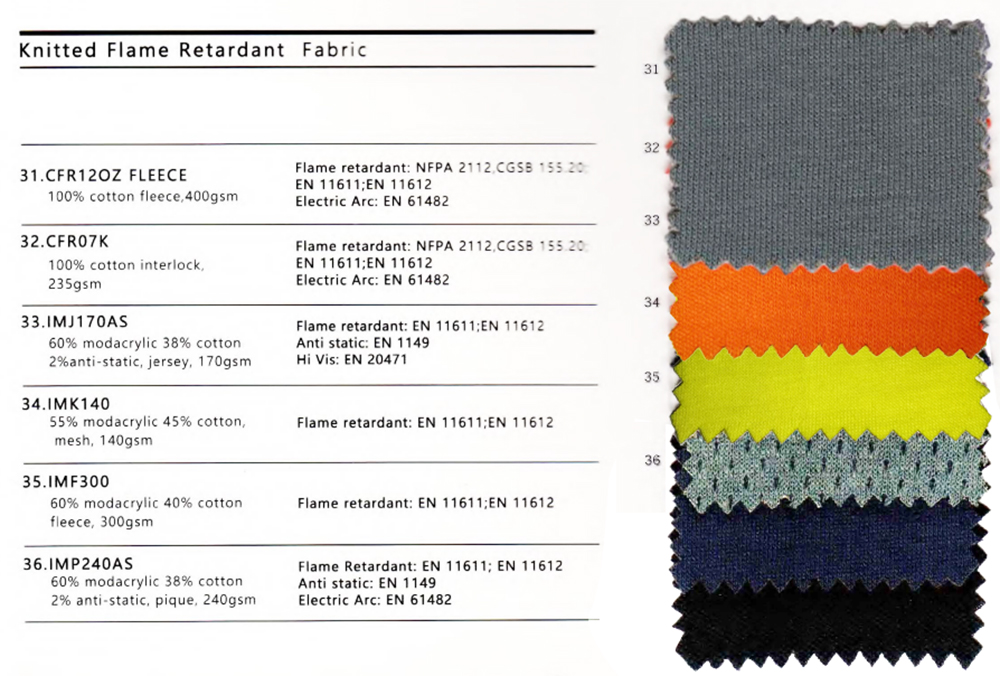

FR Knit Fabric: Stretch and Comfort with Flame Resistance

FR knit fabric is made using 针织 (knitting) techniques—think of the stretchy, flexible fabric in your favorite t-shirt, but engineered to resist flames.

How It Works: Flame Resistance in Knits

Knit fabrics start as yarns looped together, creating a breathable, elastic structure. To make them flame-retardant, manufacturers use one of two methods:

Post-treatment: Regular knit fabrics (cotton, polyester, or blends) are dipped in or coated with flame-retardant chemicals (like phosphorous or nitrogen compounds). This adds FR properties, but they may fade over time with washing or exposure to harsh conditions.

FR yarns: Knits made with inherently flame-retardant fibers (like modacrylic or FR-treated polyester) from the start. These yarns have FR properties built into their molecular structure, offering longer-lasting protection than post-treated versions.

Pros of FR Knit Fabric for Coveralls

Stretch and mobility: The looped knit structure allows for exceptional flexibility—ideal for workers needing to bend, crawl, or reach (e.g., electricians, mechanics).

Breathability: Knits have tiny air pockets, making them lighter and more breathable than woven fabrics. This is a game-changer for hot environments (think refineries in summer).

Softness: Knits feel gentler against the skin, reducing irritation during long wear.

Inherent Flame Retardant Fabric: Built-In Protection for Extreme Conditions

Inherent fabric (also called “permanent FR fabric”) gets its flame resistance from the 纤维 (fibers) themselves. The FR properties are part of the fiber’s chemical structure, not added later—so they never wash out or degrade.

Common Inherent FR Fibers

Aramids : Heat-resistant, strong, and self-extinguishing.

Modacrylic: A synthetic fiber that chars (instead of melting) when exposed to flames, releasing non-toxic fumes.

FR viscose: A cellulose-based fiber treated at the molecular level to resist burning, often blended with other FR fibers for balance.

Pros of Inherent Fabric for Coveralls

Permanent protection: No matter how many times you wash, bleach, or abuse the fabric, its FR properties stay intact. Perfect for long-term use in tough environments.

Extreme heat resistance: Inherent fibers like aramid can withstand temperatures up to 500°C (932°F), making them ideal for flash fires or electric arcs.

Durability: Woven inherent fabrics (the most common for coveralls) are tightly structured, resisting tears, abrasion, and chemical damage.