7oz Anti Arc Flame Retardant Fabric

December 09, 2025

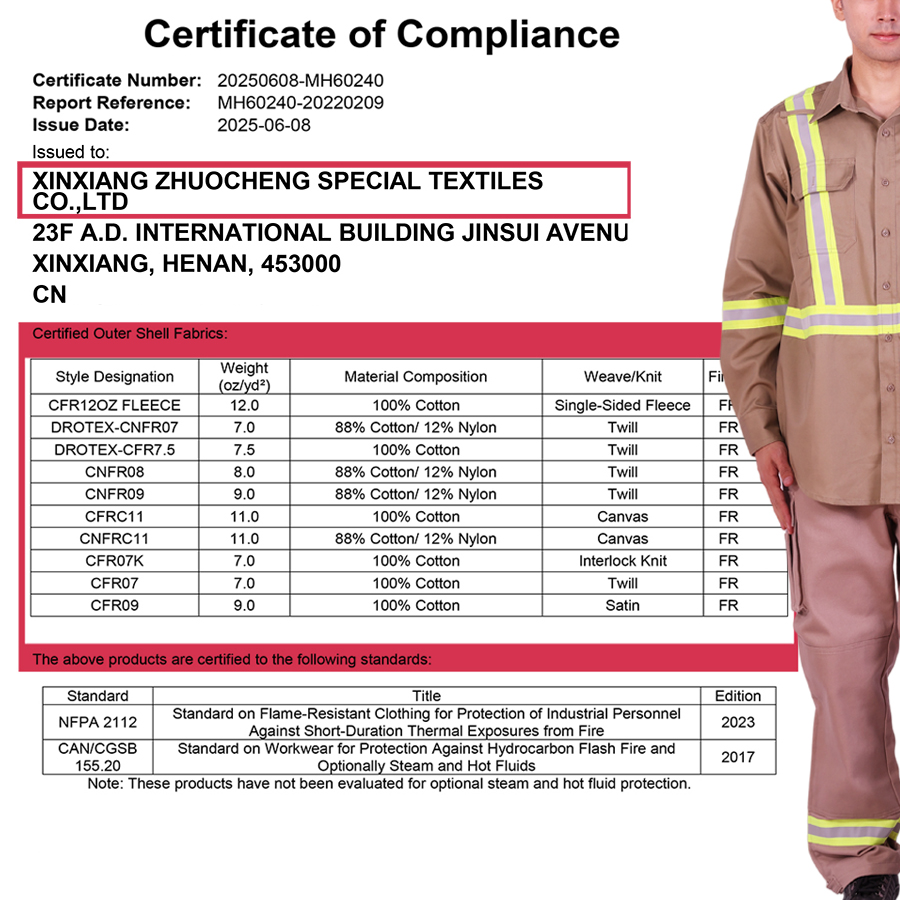

UL Certified DROTEX-CNFR07: 88% Cotton + 12% Nylon Anti Arc Flame Retardant Fabric Redefines Workplace Safety

In industries where electrical arcs, open flames, and thermal hazards lurk daily—from electrical utilities to oil refineries—protective fabric isn’t just gear; it’s a non-negotiable lifeline for workers. Traditional flame retardant FR fabrics often force a trade-off: either robust protection with stiff, uncomfortable material, or basic comfort with compromised safety. But UL Certified DROTEX-CNFR07 Anti Arc Flame Retardant Fabric, crafted with a precision blend of 88% Cotton and 12% Nylon, shatters this trade-off. This unique composition merges the natural comfort of cotton with the durable protection of nylon, all while meeting the strictest UL safety standards for arc flash and flame resistance. In this blog, we’ll dive into how this fiber blend elevates DROTEX-CNFR07’s performance, its UL certification credentials, and why it’s becoming the top choice for safety-focused organizations worldwide.

Why 88% Cotton + 12% Nylon? The Science of a Balanced Blend

The magic of DROTEX-CNFR07 lies in its intentional fiber composition. While many FR fabrics rely on synthetic fibers alone (which can feel rigid) or pure cotton (which lacks long-term durability), the 88% cotton + 12% nylon blend is engineered to deliver three core benefits: unbeatable wearer comfort, enhanced structural durability, and consistent anti-arc/flame protection. Let’s break down what each fiber brings to the table:

1. 88% Cotton: Comfort That Feels Like Everyday Wear

Cotton is a staple in everyday clothing for a reason—and in DROTEX-CNFR07, it takes center stage for comfort:

Natural Softness: Unlike synthetic FR fabrics that can feel scratchy or stiff against the skin, cotton’s inherent softness makes DROTEX-CNFR07 comfortable to wear for 8+ hour shifts. Workers no longer have to choose between safety and avoiding skin irritation or discomfort.

Breathability: Cotton fibers have a porous structure that allows air to circulate freely through the fabric. This is a game-changer for workers in hot environments—whether they’re repairing power lines under the sun or operating machinery in a factory—preventing overheating and reducing the risk of heat stress.

Moisture Absorption: Cotton naturally wicks away sweat from the skin, keeping workers dry even during strenuous tasks. Unlike polyester-based FR fabrics that can trap moisture (leading to a clammy feel), cotton’s absorbency ensures all-day freshness.

But cotton alone isn’t enough for industrial safety—this is where the 12% nylon comes in.

2. 12% Nylon: Durability & Protection That Lasts

Nylon, a high-performance synthetic fiber, is the “strength backbone” of DROTEX-CNFR07. Its addition addresses the key limitations of pure cotton (which can tear easily or lose shape over time) while boosting protective capabilities:

Tensile Strength: Nylon is 10x stronger than cotton, meaning DROTEX-CNFR07 resists tears, abrasions, and snags—critical for workers handling heavy equipment, climbing ladders, or navigating tight industrial spaces. A single snag won’t render the fabric useless, extending the garment’s lifespan.

Shape Retention: Unlike cotton, which can stretch or shrink after washing, nylon maintains the fabric’s original shape. This ensures a consistent fit (no ill-fitting sleeves or loose hems) that doesn’t compromise protection—even after 50+ industrial launderings.

Enhanced Flame & Arc Resistance: Nylon is inherently heat-resistant, and when blended with cotton (treated for permanent FR properties), it creates a synergistic effect. The nylon fibers act as a “barrier” against extreme heat, slowing down flame spread and reducing the risk of the fabric breaking open during an arc flash.

Together, this blend creates a fabric that feels like a comfortable work shirt but performs like a high-grade protective garment—encouraging workers to wear it consistently, not just when safety inspections are near.