93% meta-aramid fiber 5% para-aramid fiber 2% anti-static fiber P140.

The most prominent feature of aramid 1313 (Nomex) fabric is good high temperature resistance, can be used at 220℃ for a long time without aging, its electrical properties and mechanical properties of effectiveness can be maintained for several years, and excellent dimensional stability, at about 250℃ thermal shrinkage rate is only 1%, Short exposure to 300℃ high temperature will not shrink, embrittlement, softening or melting, only at 370℃ above the strong temperature began to decompose, about 400℃ began to carbonize, so high thermal stability in the current organic temperature resistant fiber outstanding.

Oil-gas industry, welding,mine, metallurgy, traffic, airline, paint, electrical power etc industries.

* Packaging: one plastic bag for each set,20sets~40sets in one carton or customize.

* Shipping: by sea,by air,by express delivery.

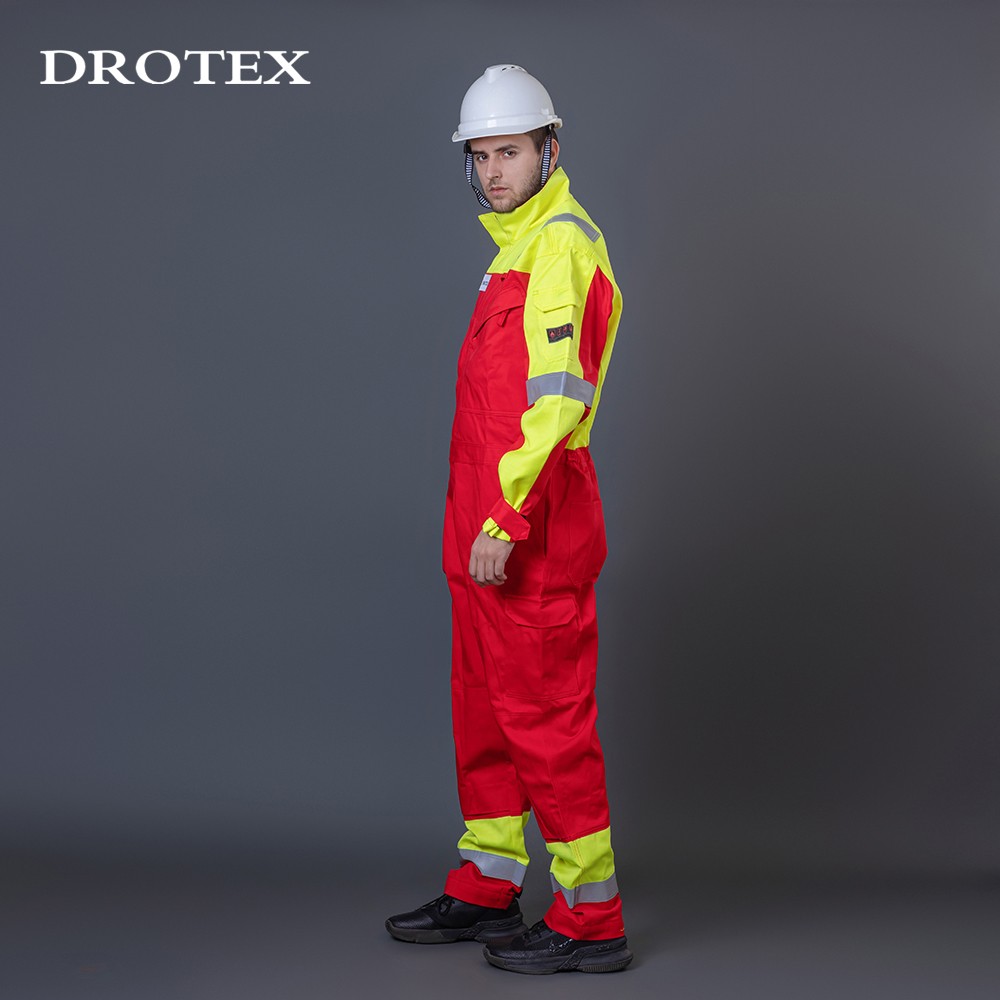

In today's fast-paced world, safety is one of the most important aspects of the workplace. Whether you are a mechanic or a welder, the implementation of fire-resistant coveralls is of paramount importance to your well-being. Aramid fibers are one of the most reliable materials for fire-resistant coveralls, and combining them with the renowned Drotex branding, you can ensure maximum protection for yourself within the workplace.

Fire-resistant coveralls made out of aramid fibers are specially designed to protect workers from the hazards of high temperatures and flames. This is achieved by the unique properties of aramid fibers that maintain their integrity under extremely high temperatures. These fibers have been used in several industries for years, ranging from military and aerospace applications to firefighting gears. However, they are now widely used in the welding and mechanical industries as well.

One of the most reliable brands for aramid fiber coveralls in the market is Drotex. The company has been a leader in the safety clothing industry for over a decade, providing high-quality products to workers worldwide. Drotex-branded aramid fiber coveralls are known for their durability, comfort, and high-temperature resistance. They provide protection from arc flash, electric shock, and flash fire while ensuring breathability and comfort to the wearer.

In conclusion, aramid fiber coveralls are a must-have for any worker dealing with high-temperature environments. By combining these coveralls with Drotex branding, you can guarantee that you are getting the best product available in the market. This will ensure your safety and well-being, as well as enhance your productivity levels. In short, investing in Drotex-branded aramid fiber coveralls is the ultimate solution for workplace safety.

EN11611: Protective clothing for use in welding and allied processes

EN11612: Protective clothing. Clothing to protect against heat and flame

EN ISO 14116: Protective clothing - Protection against fame - Limited flame spread materials,material assemblies and clothing

Protective clothing against the thermal hazards of an electric arc

EN61482-1-1: Test method: Open Arc Ranking, presented with a value. ATPV(Arc Thermal Performance Value)

EN61482-1-2: Test method: Box test. Divided in two classes, where Class 2 is the highest level

EN1149-1: Protective clothing: Electrostatic properties (surface resistivity)

EN1149-3: Protective clothing: Electrostatic properties (charge decay)

EN1149-5: Protective clothing: Electrostatic properties - Part 5: Material performance and design requirements

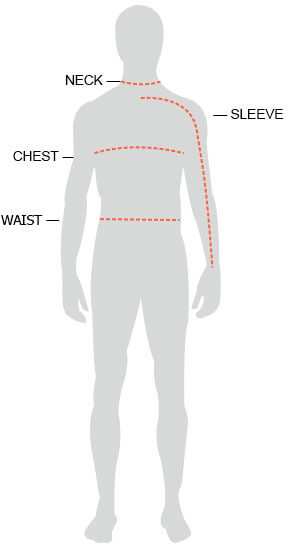

| MEN’S | SIZE | CHEST | WAIST | |||

| S | 34 | 36 | 39.5 | 41 | 34 | 35 |

| M | 38 | 40 | 42 | 43 | 36 | 37 |

| L | 42 | 44 | 45.5 | 47.5 | 40 | 42 |

| XL | 46 | 48 | 50 | 52 | 44.5 | 47 |

| 2XL | 50 | 52 | 54.5 | 56.5 | 50 | 52.5 |

| 3XL | 54 | 56 | 58.5 | 61 | 55 | 57.5 |

| 4XL | 58 | 60 | 63 | 65 | 59 | 61 |

| 5XL | 62 | - | 67 | - | 63 | - |

If you need our products please write down any questions, we will reply as soon as possible.